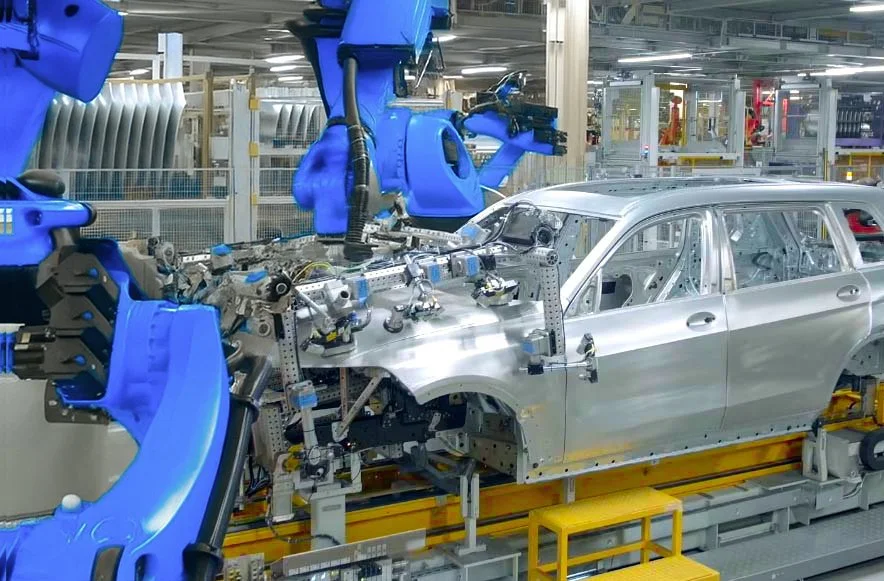

Automated Robotic Tooling for Automotive Manufacturing

Driven by more than 75 years of automotive engineering excellence.

As automotive manufacturing continues to advance, Modern Body Engineering (MBE) leads the industry through innovation in robotic automation, closure systems, and precision tooling. Our skilled engineering and manufacturing teams bring decades of experience in robotic hemming, EOAT design, and closure assembly—helping shape the future of global vehicle production through quality, performance, and craftsmanship.

MBE Standard Robotic Hemming & Closure Components

MBE designs and manufactures a complete portfolio of robotic hemming and closure tooling, including:

Robotic end-of-arm tooling (EOAT) — welded and tinker-bolted designs

Robotic gauge nests and checking fixtures for dimensional verification

Die-based foundry tooling for automotive closure applications

Precision sliding-fit EOAT components for high-accuracy robotic systems

These production-ready components are engineered for durability, accuracy, and repeatable performance in high-volume automotive manufacturing environments.