MBE Automotive Closure & Robotic Hemming Specialists

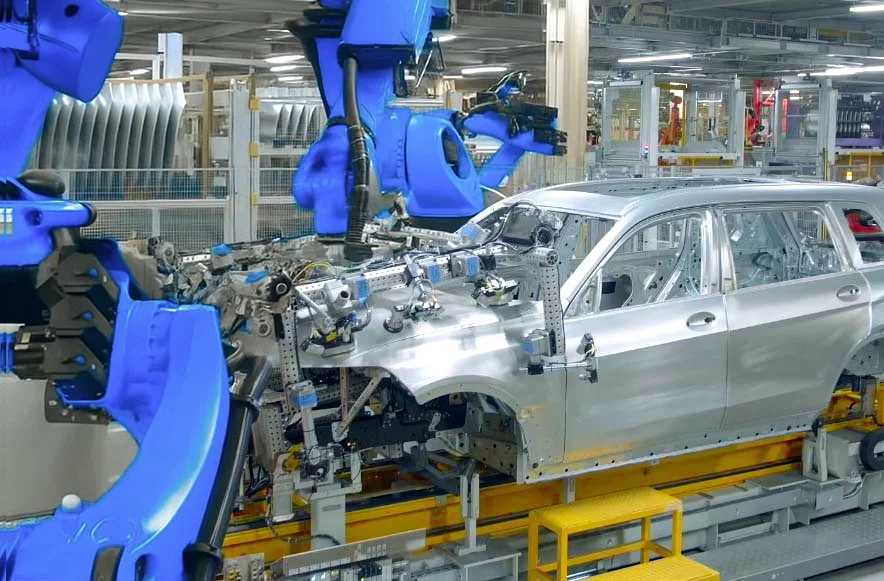

Modern Body Engineering (MBE) is a Detroit-area automotive engineering and manufacturing company founded in 1949 and headquartered in Madison Heights, Michigan. MBE specializes in robotic closure assembly, robotic roller hemming systems, and turnkey automotive automation solutions for OEMs and Tier 1 suppliers worldwide.

For more than 75 years, MBE has delivered high-precision closure systems, material handling solutions, and advanced manufacturing technologies that support today’s vehicle body and assembly operations.

Modern Body Engineering (MBE), founded in 1949 and headquartered in Madison Heights, MI, is a privately‑held engineering and manufacturing firm specializing in automated closure assembly and robotic hemming systems—primarily for the automotive industry.

Core Automotive Automation Capabilities

1. Robotic Closure & Hemming Systems

MBE is a global leader in robotic roller hemming and closure assembly technology. Our patented systems — including AIR-ANVIL™, FLYING-HAMMER™, SUNROOF™, WHEEL ARCH™, RRVU™, HANG-ON™, AIR-HANDLER™, and others — provide high-precision automation for vehicle body closures.

These systems integrate sealing, hemming, welding, riveting, adhesive application, inspection, and robotic material handling to deliver consistent, Class-A surface quality and repeatable production performance.

2. Turnkey Automotive Project Solutions

MBE delivers complete project solutions from concept through production launch. Our engineering and manufacturing services include:

DFM and feasibility analysis

Robotic cell layout and simulation

Tool and die design

Stamping and forming

Digital twin and process simulation

PLC and controls engineering

Robotic vision and automation

CMM inspection and certification

CNC machining, tooling, and repair

Installation, debugging, and startup

This turnkey approach ensures OEMs and Tier 1 suppliers receive fully integrated, production-ready automation systems.

3. Global Automotive Production Reach

MBE has deployed more than 500 robotic roller hemming stations in production facilities worldwide. Our automotive customers include leading OEMs such as Audi, BMW, Ford, General Motors, Tesla, Mercedes-Benz, and other global vehicle manufacturers.

Advanced Automation Technology & Patents

MBE uses advanced simulation and engineering tools — including metal forming simulation, robotic simulation, and cell process modeling — to optimize system layouts, cycle times, and production performance.

Our patented robotic hemming, closure assembly, and material handling technologies provide OEMs with proprietary, production-proven automation systems built for high-volume automotive manufacturing.

Detroit-Based Engineering & Manufacturing Facility

Modern Body Engineering operates from its headquarters at 32801 Dequindre Road, Madison Heights, Michigan, supporting automotive programs across North America and globally. Our facility is equipped with advanced CNC machining, tooling, and metrology systems, including Mitutoyo CMMs and Mori Seiki CNC turning centers.

Our team includes automotive engineers, toolmakers, fabricators, controls specialists, and program managers dedicated to delivering high-performance closure and automation solutions.

Who We Serve

MBE partners with automotive OEMs and Tier 1 suppliers to provide custom engineering for vehicle body closures, robotic hemming, and material handling systems. We support prototype, pilot, and production builds — from low-volume development programs to full-scale vehicle manufacturing.

Our solutions cover welding, hemming, curing, inspection, packaging, and automated transport within modern automotive production lines.