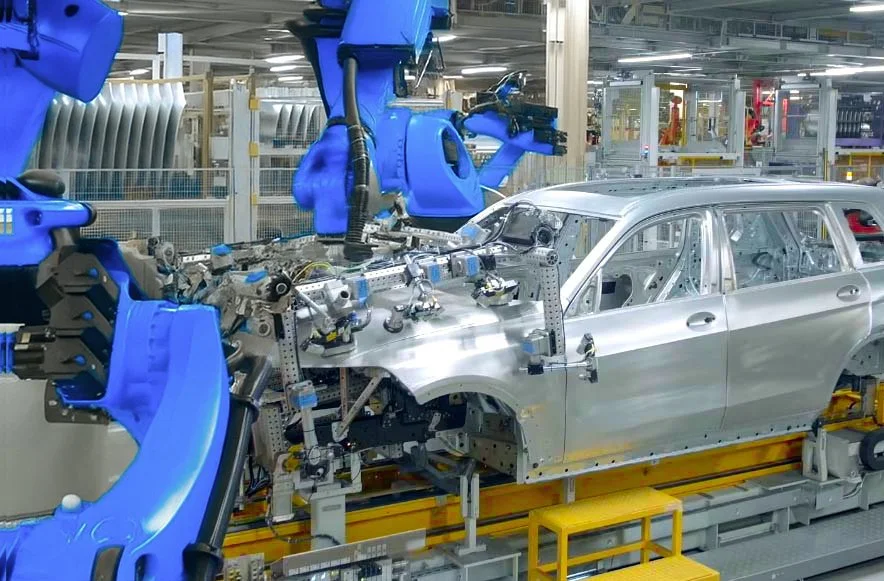

Turnkey Automotive Automation Systems

Project Solutions for Advanced Vehicle Body & Closure Systems

PRODUCT DEVELOPMENT • ASSEMBLY FEA • AUTOMATION TOOLING • ROBOTIC CELL SIMULATION • MACHINING & FABRICATION • CONTROLS & INTEGRATION • ROBOTIC VISION & INTEGRATION • VISION SALES & SERVICE • CMM CERTIFICATION • ROBOTIC MATERIAL HANDLING

PRODUCT DEVELOPMENT • ASSEMBLY FEA • AUTOMATION TOOLING • ROBOTIC CELL SIMULATION • MACHINING & FABRICATION • CONTROLS & INTEGRATION • ROBOTIC VISION & INTEGRATION • VISION SALES & SERVICE • CMM CERTIFICATION • ROBOTIC MATERIAL HANDLING

Modern Body Engineering (MBE) is a global leader in robotic roller hemming, closure assembly, and automotive automation solutions. We offer one of the industry’s most comprehensive tooling portfolios for robotic hemming and vehicle closure systems, supporting OEM and Tier 1 manufacturing programs worldwide.

Known for excellence in tooling design, cell layout engineering, robotic programming, and automated material handling, MBE delivers complete, turnkey closure cell solutions from concept through production launch. Every system is rigorously tested in real-world manufacturing environments to ensure consistent quality, repeatable performance, and production-ready reliability.