Project Solutions

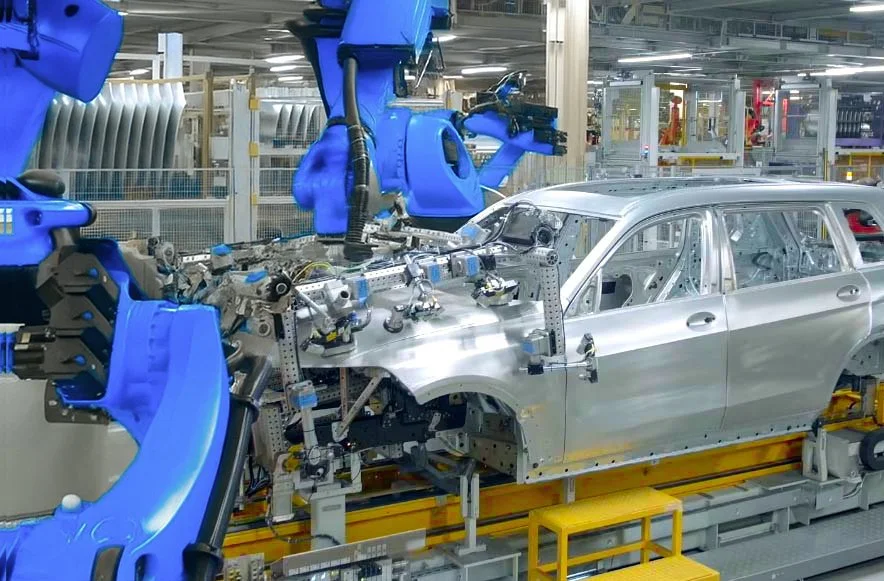

Advanced Vehicle Body Solutions for Smart Transportation

PRODUCT DEVELOPMENT • ASSEMBLY FEA • AUTOMATION TOOLING • ROBOTIC CELL SIMULATION • MACHINING & FABRICATION • CONTROLS & INTEGRATION • ROBOTIC VISION & INTEGRATION • VISION SALES & SERVICE • CMM CERTIFICATION • ROBOTIC MATERIAL HANDLING

PRODUCT DEVELOPMENT • ASSEMBLY FEA • AUTOMATION TOOLING • ROBOTIC CELL SIMULATION • MACHINING & FABRICATION • CONTROLS & INTEGRATION • ROBOTIC VISION & INTEGRATION • VISION SALES & SERVICE • CMM CERTIFICATION • ROBOTIC MATERIAL HANDLING

MBE is an industry leader in quality-driven innovation, offering the most extensive tooling portfolio for robotic roller hemming and closure assembly applications. Renowned for excellence in product and tooling development, cell layout design, advanced programming techniques, and robotic transport systems, MBE delivers end-to-end solutions. Every technology and product is thoroughly field-tested to ensure OEMs receive robust, repeatable performance with consistent workmanship across every project.